Process FlowKorea Circuit is at the center of the smart world.

Inspection

Process to check the product exterior and quality characteristics using visions and magnifiers

- Final inspection

- This is a 100% test. Mainly, the quality of the exterior is checked visually, or by AFI(Automatic Final inspection) or magnifiers.

- Outgoing/reliability inspection

- Exterior dimensions, hole sizes, and product thickness are tested. Shipping report is prepared.

Process photos (main facility)

Final inspection (inspection equipments)

- Equipment name

- AFI (Automatic Final Inspection)

- Model

- AVIS-3600, AVIS-3600Wide

- Maker

- ATI

- Test items

- Auto cosmetic test

- Content

- PCB Tab, Pad and other alien substances related cosmetic tests.

- Equipment name

- VRS(Verify Rework Station)

- Test items

- Auto cosmetic test

- Content

- Non-conformance analysis

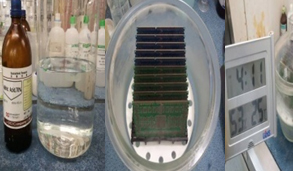

Reliability equipment

Environment test equipment

-

- Equipment name

- Thermal shock chamber / Conduction tester

- Use and conditions

-

- After shipping the product, this guarantees resistance to damage related to exposure (temp change-high/low temperature). (When the exposed environment (temp change) exists, it guarantees reliability against resistance changes.)

- -55℃(15min) ↔ 125℃(15min)

100 ~ 1000Cycle

-

- Equipment name

- Humidity chamber/ Ion migration tester

- Use and conditions

-

- After shipping the product, this guarantees resistance to damage related to exposure (temp/humidity change). (When the exposed environment (temp/humidity change) exists, it guarantees ion migration(insulation resistance drop).)

- - 50℃ / 85% / 5V / 600hr

-

- Equipment name

- PCT (Pressure Cooker Tester)

- Use and conditions

-

- Exposed to high temp/pressure for certain time. This guarantees the reliability of the product.

- 121℃ / 2atm / 8~96hr

-

- Equipment name

- Hot oil tester

- Use and conditions

-

- After shipping the product, this guarantees resistance to damage related to exposure (temp change-high/room temperature).

- 260℃(10sec) ↔ 20℃(20sec) 30Cycle

-

- Equipment name

- Solder pot

- Use and conditions

-

- roduct’s heat resistance and solderability test

- Solder heat impact: 260℃ / 288℃ / 10sec, Solderability: 245℃ / 4sec

-

- Equipment name

- B-HAST (Bias Highly Accelerated Temperature And Humidity Stress Test)

- Use and conditions

-

- In high speed, high temperature/humidity conditions, this guarantees the reliability and checks the electrical characteristics.

- 130℃ / 85% / 96~168hr

Analysis equipment

-

- Equipment name

- SEM(Scanning Electron Microscope) & EDS(Energy Dispersive Spectroscope)

- Use and conditions

-

- High zooming ratio observation and inorganic material analysis.

- X30 ~ X300,000 observation / inorganic material analysis (Au / Ni / P, etc.)

-

- Equipment name

- FT-IR Micro scope (Fourier Transform Infrared Spectrophotometer)

- Use and conditions

-

- Organic material analysis (liquid/solid)

- Organic material analysis (PSR / Tape / Dry film, etc.)

Measurement equipment

-

- Equipment name

- Micro scope

- Use and conditions

-

- High zooming ratio observation(X25 ~ X2,000) / photo taking(JPG files, etc) / dimension measurements(length, etc)

- Post micro section observation / fine sample with high zooming ratio observation.

-

- Equipment name

- Non-Contact Surface Profiler

- Use and conditions

-

- Fine surface roughness measurement (chemical treatment/ Jet scrub / CZ treatment and etc.)

- Vertical measurement range: 0.1nm~1.0mm / resolution: 3Å, accuracy: 0.01nm

-

- Equipment name

- DSC Tg tester (Differential Scanning Calorimeter)

- Use and conditions

-

- Glass transition temperature measurement on cores and stacked layer products.

- Normal / Middle / High / Halogen free material ramp temp control.

-

- Equipment name

- TMA tester (Thermo Mechanical Analyzer)

- Use and conditions

-

- Final product/raw material(Core) Delamination verification

- T260 / T288

-

- Equipment name

- SAM tester (Scanning Acoustic Microscope)

- Use and conditions

-

- Final product/semi final product(after lamination)/raw material bubbles/ Delamination verification

- Post reflow T-Scan

-

- Equipment name

- Tensile strength tester (Elongation tester)

- Use and conditions

-

- Cu plating tensile strength test/ Peel strength test / Push test (Repair)

- Width: 10mm / Peel speed: 50mm/min

-

- Equipment name

- Ionic Contamination Tester

- Use and conditions

-

- Product surface Nacl contamination test

- IPA 75%/10min

-

- Equipment name

- Low resistance tester (mΩ Tester)

- Use and conditions

-

- Zocus resistance measurement / LVH Coupon resistance measurement

- mΩ ~ ㏀ (fine resistance measurement)

-

- Equipment name

- Insulation Resistance Tester / Withstand voltage tester

- Use and conditions

-

- Surface to layer insulation resistance measurement/surface to layer withstand voltage measurement

- Insulation resistance: DC 100V /1000V / 30sec, withstand voltage: DC 500V/1000V 30sec

-

- Equipment name

- IST (Interconnect Stress Test)

- Use and conditions

-

- IST Coupon used to predict the lifetime of PTH, BVH, LVH depending on the thermal damage.

- 150℃, 150 cycle or 1000 cycle conditions for testing.

Other equipment

-

- Equipment name

- Porosity(nitric acid vapor test)

- Use and conditions

-

- AU plating surface analysis(corrosion)

- Use the given temp/humidity condition in the desiccator to expose it to the nitric acid for one hour.

-

- Equipment name

- Salt water spray

- Use and conditions

-

- AU plating surface analysis(corrosion)

- Use the salt water sprayed from the sprayer to expose it for a certain hour.

-

- Equipment name

- Polishing M/C

- Use and conditions

- Product destruction test (vertical/horizontal)

-

- Equipment name

- Drier(forced circulation dry oven)

- Use and conditions

- Baking condition(121 ~ 149℃) execution and product drying.