Process FlowKorea Circuit is at the center of the smart world.

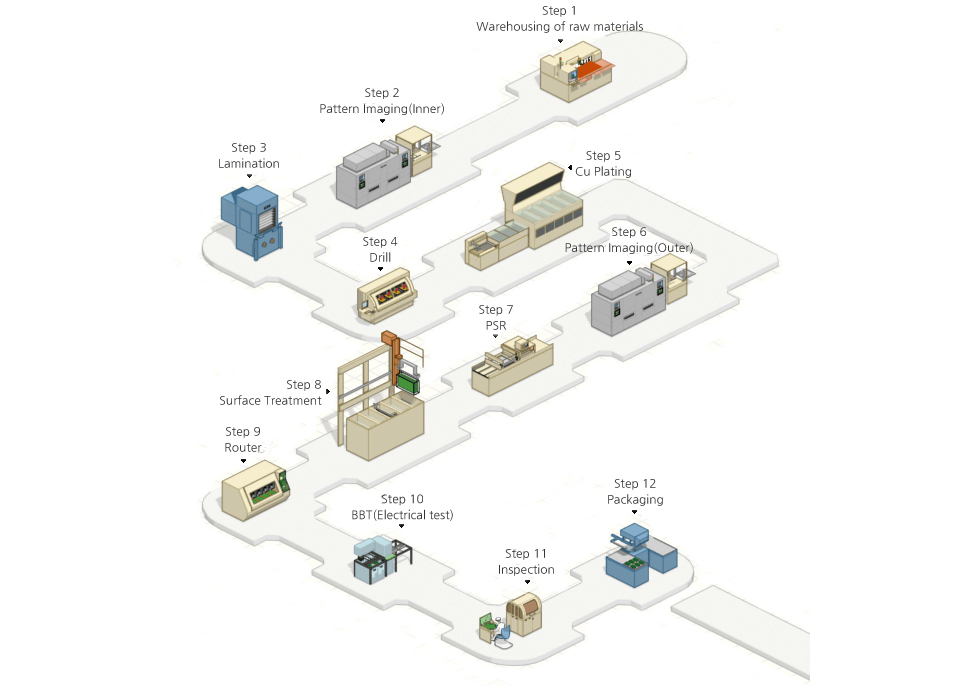

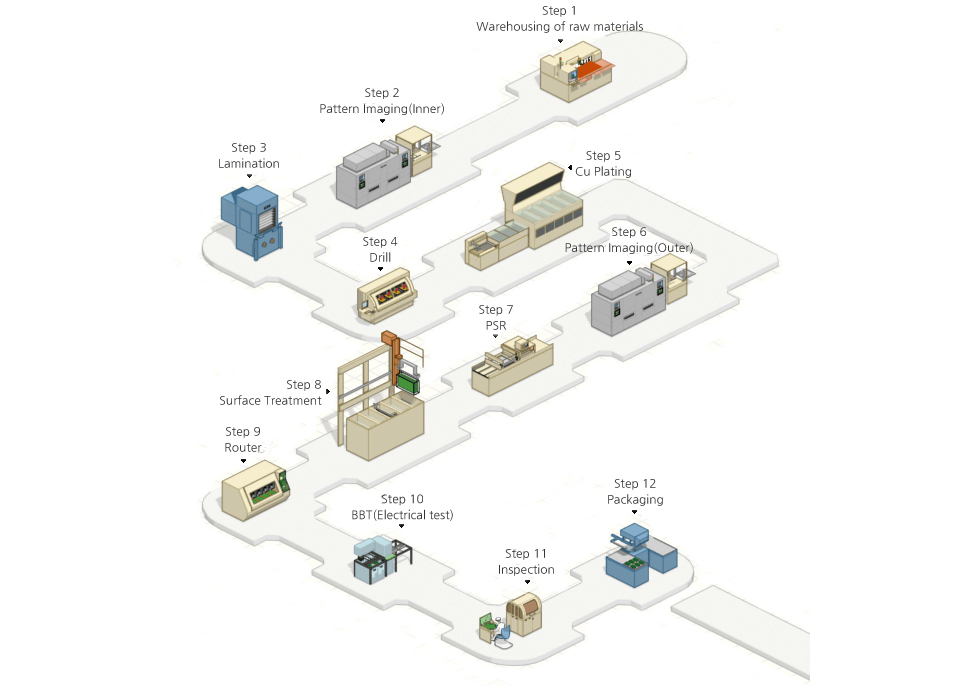

- 1. Warehousing of raw materials

- Warehoused raw materials are released to each process after incoming inspection.

- 2. Pattern imaging(inner)

- The copper layer is corroded to form the circuit. The circuit is formed on the core of the inner layer. (exposure, development, corrosion)

- 3. Lamination

- Using heat and pressure, the inner layer core and the insulator are combined together.

- 4. Drill

- The process that connect electrical properties between inner and outer layers by using drill bit and laser to make hole.

- 5. Cu Plating

- The product's surface and the inside of the hole are coated with copper to combine the inner and outer layers.

- 6. Pattern imaging(outer)

- The copper layer is corroded to form the circuit. The circuit is formed on the core of the inner layer. (exposure, development, corrosion)

- 7. PSR

- Using non changeable ink, the non usable areas are coated.

- 8. Surface Treatment

- To prevent oxidation and support easy SMT, the usable area

(copper layer without ink coating) surface is coated.

- 9. Router

- Using bits, the panel is cut to the size desired by the customer.

- 10. BBT(Electrical test)

- Electrical test to verify circuit connections.

- 11. Inspection

- Process to check the product exterior and quality characteristics using visions and magnifiers

- 12. Packaging

- Vacuum packaging and fillers are used for shipping.